Capabilities

KUS has design and engineering, tooling and molding, validation and testing, and manufacturing capabilities for marine, vehicle, and industrial industries. Discover how KUS can best serve your needs and explore our wide array of capabilities.

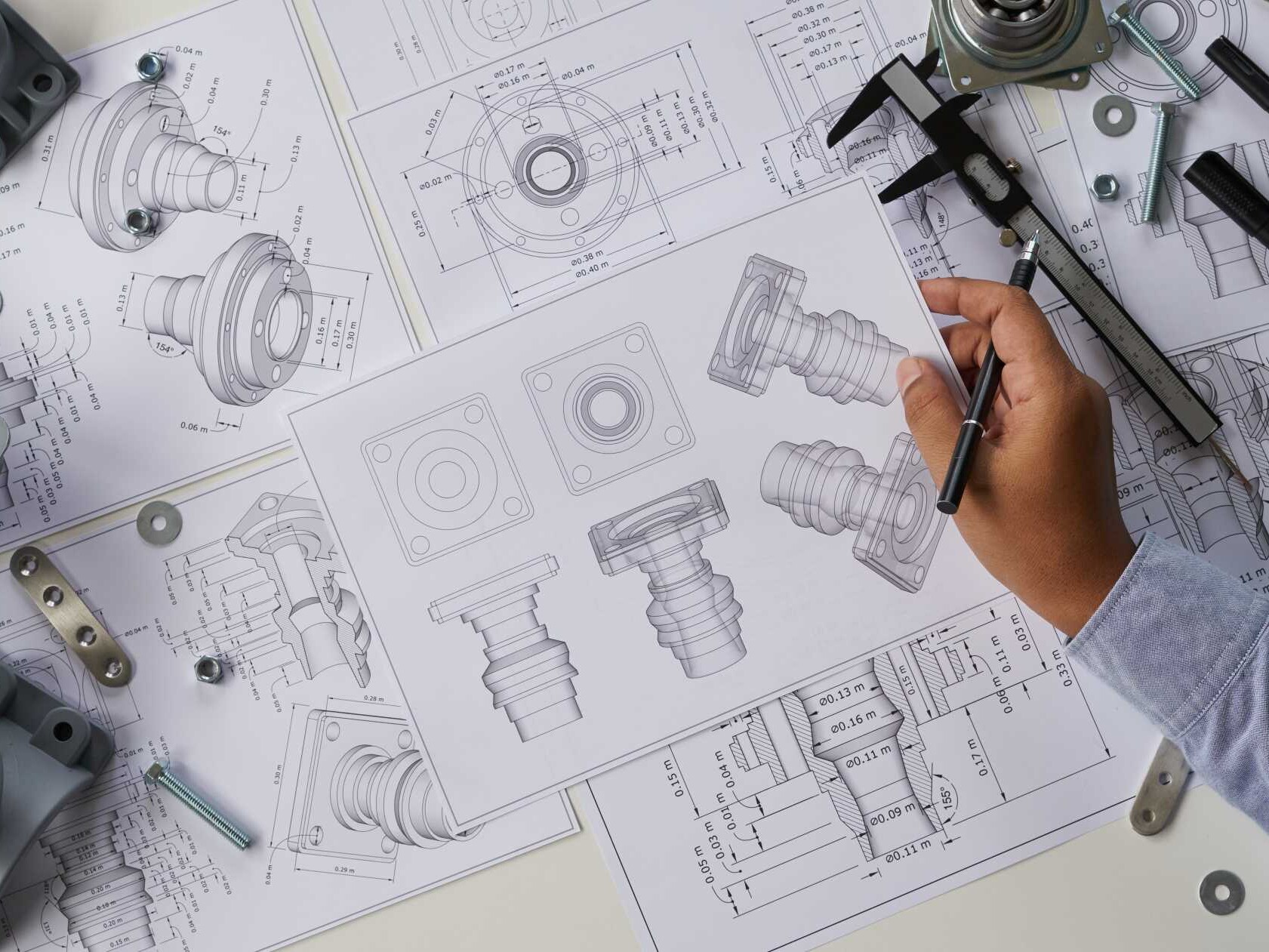

Design & Engineering

KUS (formerly known as WEMA) employs mechanical, electrical, and software engineers to support our product development. Each of our experts plays an important role in the plastics manufacturing process. Some of these experts focus on CAD design and analysis, while others are responsible for conducting detailed Design for Manufacturability (DFM) analysis. Together, our team ensures our plastic products are manufactured to the highest engineering and design standards.

Tooling & Fixtures

At KUS, all blow molding, rotational molding, die-casting, rubber, and modeling molds are designed, produced, and debugged internally. We can design tooling options that comprehensively meet all manufacturing needs. By effectively partnering with customers for new product development work, we are able to produce tooling and fixture options that can meet any project requirements.

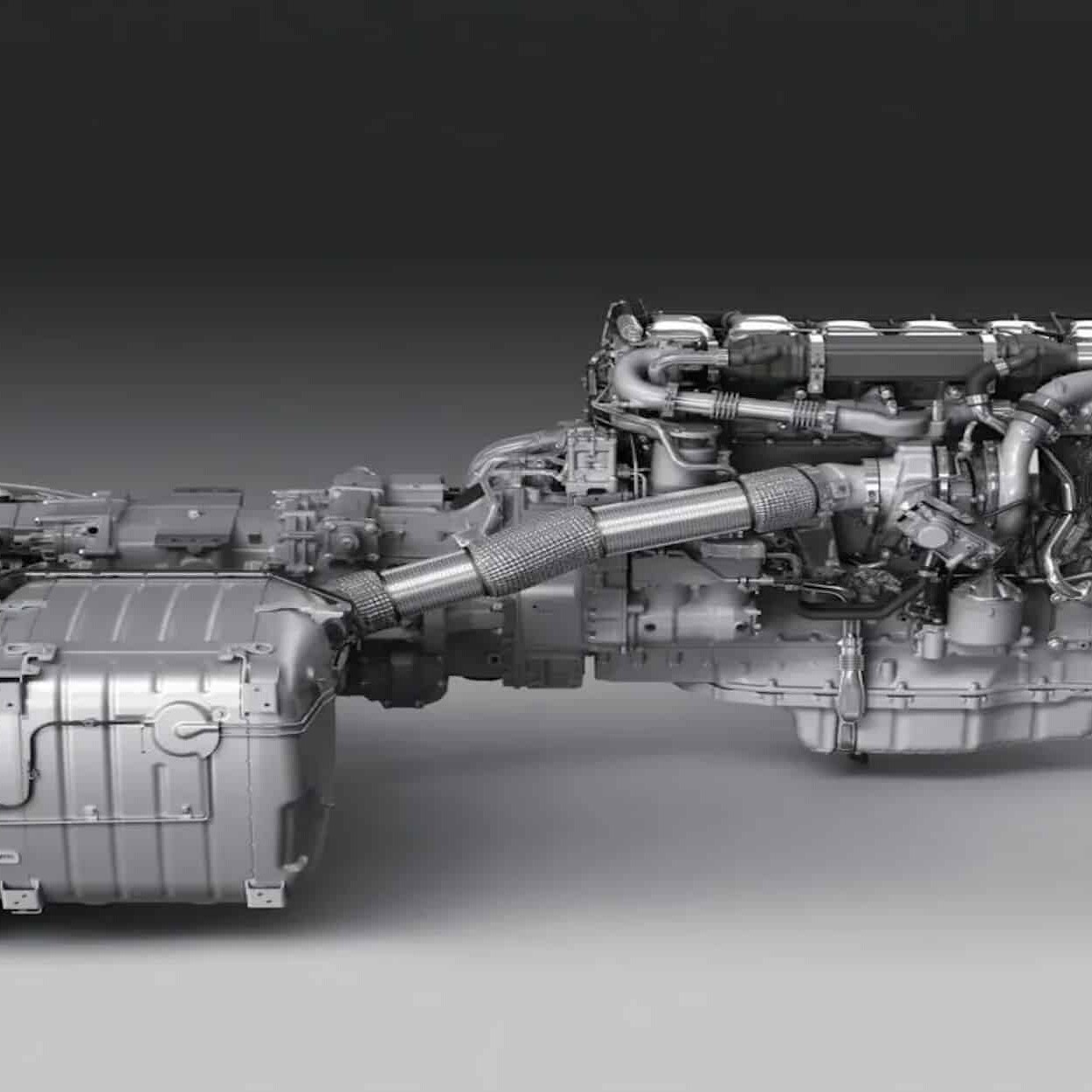

Manufacturing

KUS offers a wide array of manufacturing capabilities for our OEM partners. Whether you require CNC machining or access to brazing technologies, our team is able to fulfill your needs.