A major responsibility shared by commercial and industrial vehicle manufacturers is to be aware of and help reduce the environmental impact of emissions, as well as stay up to date on any current standards and technologies. Increased awareness of this issue has led to strict emissions regulations worldwide to curb pollutants that contribute to air quality degradation and climate change. Among the technologies developed to meet these rigorous standards, Selective Catalytic Reduction (SCR) systems stand out as an important innovation.

SCR systems are essential in reducing the output of harmful emissions from a variety of sources, including commercial vehicles and industrial equipment. They have become integral components in achieving cleaner air, representing a significant leap forward in environmental technology.

The SCR System Explained

SCR systems represent a convergence of chemistry and engineering, providing a pathway to cleaner air and a healthier environment. The following will help to outline and define what SCR means, the system’s role in emissions reductions, and how it works to mitigate pollutants.

What Does SCR Stand For?

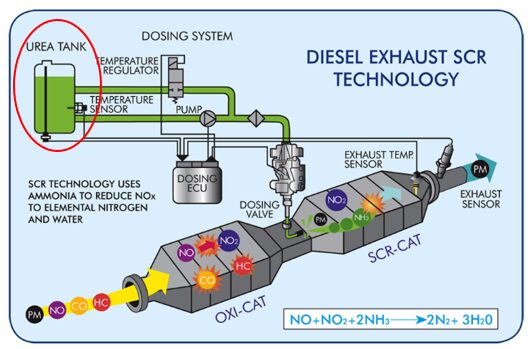

Selective Catalytic Reduction (SCR) is a means of converting nitrogen oxides, also known as NOx emissions, into harmless nitrogen (N2) and water (H2O) through the use of a catalyst system. This process is crucial because NOx is a primary component of smog and acid rain and is a significant contributor to the greenhouse effect. It essentially helps to turn the application into a cleaner burning vehicle, while still maintaining easy and common fuel options.

The Significance of SCR in Emissions Reduction

SCR technology is vital for regulatory compliance and protecting public health and the environment. By significantly reducing NOx emissions, SCR systems help prevent the formation of ground-level ozone and fine particulates, which are hazardous to respiratory health.

SCR Aftertreatment Systems and Common Emissions

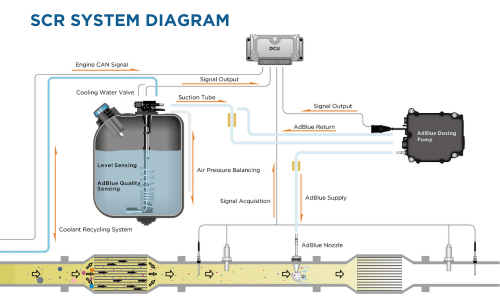

Major components in the SCR exhaust aftertreatment system include a DEF supply module or injector, a DEF tank assembly, and an SCR catalyst. These components work together to reduce harmful emissions that would otherwise be expelled from the vehicle, including:

- Particulate Matter (PM). These tiny particles can penetrate deep into the lungs and are a serious health risk. SCR systems help to trap and burn off these particles.

- Hydrocarbons (HCs). Unburned fuels that form toxic compounds. An SCR system, in conjunction with other treatments like Diesel Particulate Filters (DPFs), can reduce the release of HCs.

- Nitrogen Oxides (NOx). NO and NO2 emissions contribute to the formation of smog and acid rain. The core function of SCR systems is to reduce these NOx emissions.

SCR systems are widely used across sectors, including in commercial on-road and off-road vehicles, and in industrial applications. The aftertreatment process varies according to the system and its application but generally involves injecting a urea solution (commonly known as Diesel Exhaust Fluid (DEF), or AdBlue®) into the exhaust stream, which then reacts with the NOx over a catalyst.

How Does the SCR System Work?

An SCR system begins its work where the combustion process ends. Exhaust gasses containing high levels of NOx enter the SCR catalyst. Here, a dosing valve injects DEF into the exhaust, which decomposes into ammonia (NH3). This ammonia then reacts with NOx on the catalyst’s surface to form harmless nitrogen and water vapor output.

Active SCR Systems vs. Passive Catalytic Converters

SCR systems in diesel engines represent a more active approach to emissions control compared to the passive catalytic converters found in gasoline vehicles. While catalytic converters act like a filter that traps harmful emissions, SCR systems actively inject Diesel Exhaust Fluid (DEF) into the exhaust, which chemically reacts with nitrogen oxides (NOx) to form harmless nitrogen and water. This active process is continuously adjusted based on real-time engine data, ensuring efficient NOx reduction across various operating conditions.

The advantage of SCR systems lies in their precision and adaptability, unlike the passive nature of catalytic converters. SCR systems dynamically manage emissions, resulting in more effective pollution reduction, making SCR an essential technology for meeting modern environmental standards and advancing eco-friendly automotive technologies.

Advantages of Using SCR Systems:

- Effective NOx Reduction. SCR can reduce NOx emissions by up to 90%.

- Fuel Efficiency. SCR technology allows engines to operate more efficiently, thus conserving fuel.

- Longevity. SCR systems are designed to last the lifetime of the vehicle or application with proper service.

Potential Drawbacks:

- Initial Cost. Installation of SCR systems can be expensive, although they are cost-effective in the long run.

- Maintenance. The need for additional fluids (like DEF) and periodic servicing can be seen as drawbacks by some operators.

SCR Products From KUS

KUS is a global leader in SCR system components manufacturing. With more than two decades of expertise, KUS has developed a range of products that exceed industry standards. Here are some of the top SCR system components manufactured in-house by KUS.

Standard DEF Tank Assemblies

Our standard DEF tank assemblies come in various sizes, including 5, 10, and 15 gallons, and are available in both landscape and portrait orientations. These assemblies include a DEF tank, level sensor, and quality sensor engineered to comply with J1939/OBD standards for commercial use.

To ensure broad application compatibility, each assembly is rigorously tested and validated for both on-road and off-road conditions, providing versatility across various market segments. Additionally, KUS DEF tank materials are selected for their durability and resistance to harsh chemicals and settings, ensuring a long service life even in the most demanding environments.

Custom DEF Tank Options

KUS also specializes in custom DEF tanks for precise application needs where space claim may be limited or unique. Our custom DEF tank solutions include:

- Exact Dimensions. Custom-shaped tanks using HDPE and blow molding for a perfect fit.

- Stress Testing. Ensuring durability that meets your specific requirements.

- Signal Customization. Analog or digital signal options for clear, quick readings.

- Brand Recognition. Aesthetic modifications like branding for a distinctive look.

- Integrated Measurement. DEF Level Sender and Temp Sensor for monitoring temperature and fluid levels.

- Quality Sensors. Sensors to assess urea solution concentration for SCR system efficacy.

Our custom DEF assemblies provide both functional superiority and brand distinction, tailored to your specifications.

Quality Sensors

We equip our tanks with integrated DEF quality sensors to measure urea concentration, ensuring the SCR system functions at peak efficiency. KUS DEF quality sensors are designed using cutting-edge technology to provide accurate readings and withstand the rigors of continuous operation, contributing to the longevity of the SCR system. Our team of engineering experts have designed KUS DEF quality sensors to easily integrate into existing systems, enabling seamless upgrades, service, and replacements as needed.

Find More DEF, AdBlue®, and SCR Products From KUS

KUS continues to uncover new innovations in eco-friendly technologies. Our comprehensive portfolio of DEF tanks, DEF/AdBlue®, and exhaust aftertreatment products exemplifies our commitment to environmental stewardship and our customers’ needs. Browse our full selection of SCR products to find the perfect solution for your emissions control requirements. Please don’t hesitate to contact us for more information about any of these products and our custom solutions.