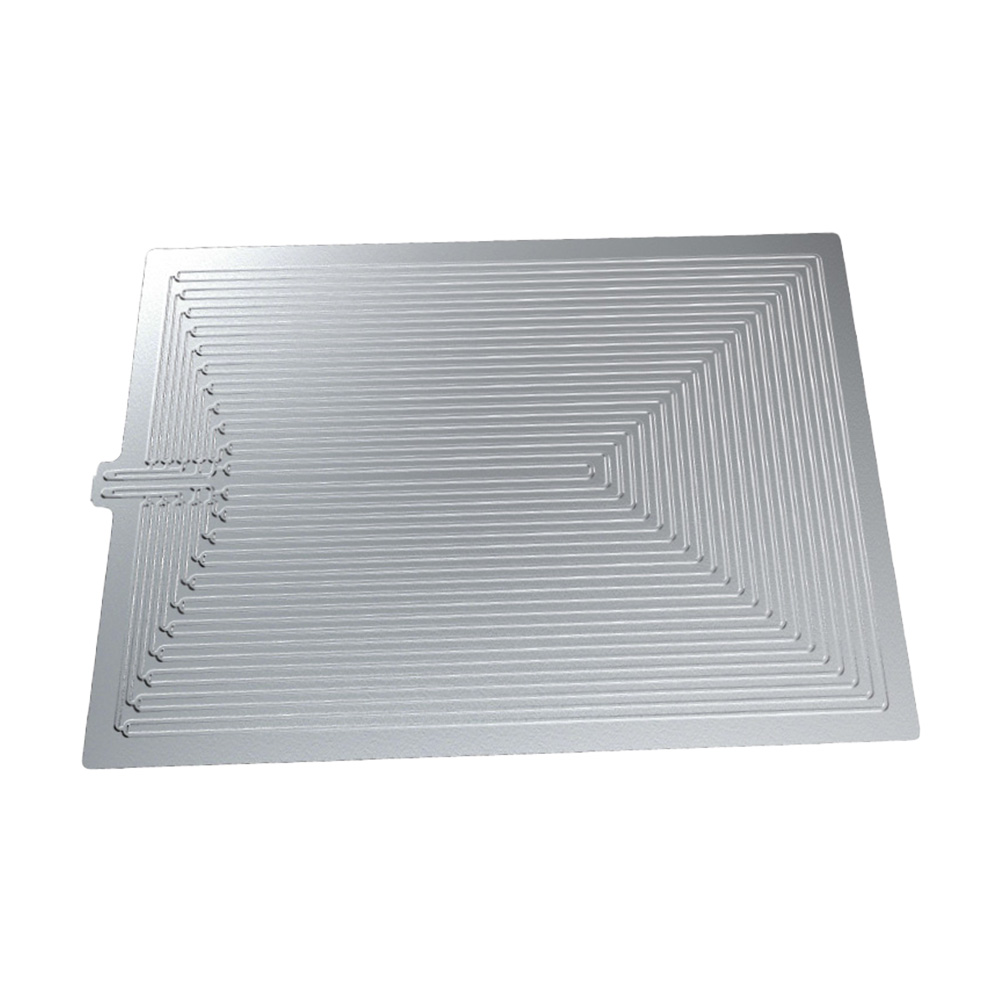

Cold Plate

Liquid cold plates, also known as liquid cooling plates, are an essential component in the thermal management systems (TMS) of electric vehicles (EVs) and hydrogen fuel cell vehicles (FCVs). They are pivotal in managing heat in high-performance components like batteries, electric motors, and fuel cells.

How Liquid Cold Plates Work

A liquid cold plate, typically crafted from materials with high thermal conductivity, such as aluminum or copper, functions as a conduit for a coolant (liquid or gas) to flow through. These plates efficiently transfer heat from the component (e.g., battery or fuel cell) to the liquid cold plate’s surface. The heat transmitted to the coolant circulates through the system, carrying the heat away and dissipating it, often through a heat exchanger.

Key Advantages of Liquid Cold Plates

Compared to traditional air-cooling methods, the importance of liquid cold plates, or liquid cooling plates, in TMS becomes evident:

Efficient Heat Transfer:

Liquid cold plates transfer heat efficiently, maintaining optimal operating temperatures for crucial components. This is vital for preserving performance, enhancing efficiency, and extending component lifespans.

Compact Design:

Liquid cold plates are thin and lightweight, making them ideal for the tight spaces within EVs and FCVs. They can be directly affixed to heat-generating components, reducing thermal resistance and improving heat transfer.

Enhanced Safety and Reliability:

By effectively managing heat, liquid cold plates prevent component overheating, mitigating the risk of thermal runaway, especially in batteries. This enhances vehicle safety and reliability.

Versatility:

Liquid cold plates can be customized to fit various shapes and sizes, making them adaptable to a wide range of applications within the vehicle.

Reduced Noise Levels:

Liquid cold plates operate quietly without noisy fans, contributing to a quieter overall vehicle experience.

Material Characteristics

- 4045/3003, 4045/3003 MOD composite plate stamping forming

- Common material thickness 0.8, 1.0, 1.2mm, alloy/state: 003-0 state,3003 MOD-O state

- Tensile strength: 95~135MPa (3003), ⩾145MPa (3003)

- Material elongation: ⩾25% (3003), ⩾20% (3003 MOD)