Positive Temperature Coefficient (PTC) Heating Unit

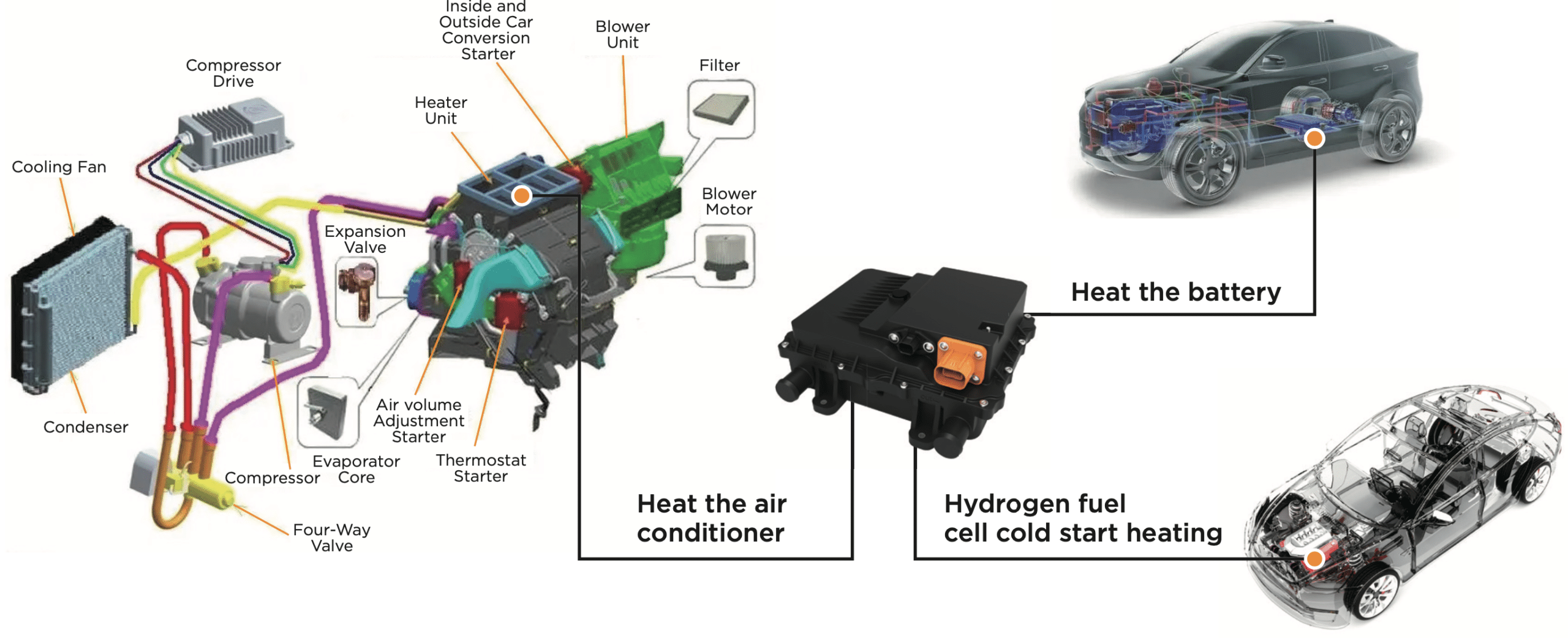

KUS Positive Temperature Coefficient (PTC) coolant heating units are used in pure battery electric, hybrid electric, and fuel cell vehicles. PTC heaters utilize electricity to supply efficient heat control for various vehicle systems, including in-vehicle air conditioning and battery thermal management.

Cabin Heating

In traditional internal combustion engine vehicles, waste heat is harnessed from the engine to warm the cabin. However, EVs and FCVs produce less waste heat, necessitating an innovative cabin heating approach. PTC heaters provide an efficient solution by generating heat through electrical resistance, swiftly warming the cabin during cold conditions.

Battery/Fuel Cell Heating

Maintaining optimal operating temperatures for batteries in EVs and fuel cells in FCVs is critical for their performance, efficiency, and longevity. PTC heaters excel, efficiently warming these components in cold conditions. This is particularly crucial for batteries, which can experience reduced capacity and potential damage at very low temperatures.

Self-Regulating Technology

The term “positive temperature coefficient” characterizes PTC heaters as their electrical resistance rises with temperature. This intrinsic feature renders PTC heaters self-regulating, reducing power output as they heat up to prevent overheating. This simplifies control systems and enhances vehicle safety, overall efficiency, and TMS reliability.

Efficiency and Reliability

PTC heaters provide a versatile and efficient solution for heating requirements in EVs and FCVs, significantly contributing to vehicle performance and passenger comfort.

Product Features

Application:

Ideal for pure battery electric, hybrid electric, and fuel cell vehicles.

Versatile Use:

Efficiently controls heat for various vehicle systems, including in-vehicle air conditioning and battery thermal management.

Automated Heating:

Offers an automated heating system.

Enhanced Heating:

Generates more heat than traditional heating elements, reducing electricity consumption.

Benefits:

Improves cruising range safety, lowers costs, and offers a more compact format.

Product Structure

PTC heaters feature a comprehensive structure, including radiators (housing PTC heating packs), coolant flow channels, a central control board with high/low-pressure connectors, and an upper shell. This design ensures stable power delivery, high heating efficiency, and consistent temperature control for various applications and scenarios.

Models and Specifications

| Model | NPA10 | NPL20 | NPH30/NPH30A | NPK40 | NPH50 |

|---|---|---|---|---|---|

| Specification | 80V-3kW | 350V-5kW | 600V-7kW | 800V-10kW | 600V-15kW |

| Power | 3kW±10% | 5kW±10% | 7kW±10% | 10kW±10% | 15kW±10% |

| Rated conditions | Coolant=0°C, 10L/min | Coolant=60°C, 10L/min | Coolant=0°C, 10L/min | Coolant=60°C, 12L/min | Coolant=0°C, 25L/min |

| Application scenarios | Forklift Fuel System | Passenger car\ Gas power system |

Commercial Vehicle\ Gas Power System |

New energy air condition system |

Commercial vehicle\ Gas Power System |

| Ambient temperature | -40°C-85°C | -40°C-85°C | -40°C-85°C | -40°C-85°C | -40°C-85°C |

| Storage temperature | -40°C-105°C | -40°C-105°C | -40°C-105°C | -40°C-105°C | -40°C-105°C |

| Cooling water temperature | -40°C-90°C | -40°C-90°C | -40°C-90°C | -40°C-90°C | -40°C-90°C |

| Low voltage | 9V-36V, Un=12/24V | 9V-36V, Un=12/24V | 9V-36V, Un=12/24V | 9V-36V, Un=12/24V | 9V-36V, Un=12/24V |

| Low voltage current | <150mA | <150mA | <150mA | <150mA | <150mA |

| High voltage | 70V-110V, Un=80V | 250V-450V, Un=350V | 450V-750V, Un=600V | 750V-875V, Un=800V | 400V-750V, un=600V |

| High voltage current | <80A | <30A | aaaaaa | <40A | <60A |

| Insulation resistance | >100MΩ | >100MΩ | >100MΩ | >200MΩ | >200MΩ |