In the rapidly advancing world of electric vehicles (EVs) and hydrogen fuel cell vehicles (FCVs), a key technical challenge lies in the realm of thermal management systems (TMS). These systems ensure the effective operation of critical vehicle components – primarily the battery in EVs and the fuel cell in FCVs. Today, we will delve into the intricacies of TMS, explaining their roles, components, and the unique complexities they present.

The core function of a TMS in EVs and FCVs is to regulate the temperature of the battery or fuel cell, respectively. This is critical as thermal management influences performance, safety, efficiency, and the lifespan of these components.

Integral Components of a Battery/Fuel Cell TMS

A well-designed TMS for EVs and FCVs features several key components, including:

- Thermal Interface Materials (TIMs): These materials ensure efficient heat transfer between the battery or fuel cell and the heat sink, helping to avert local overheating that can result in system failure.

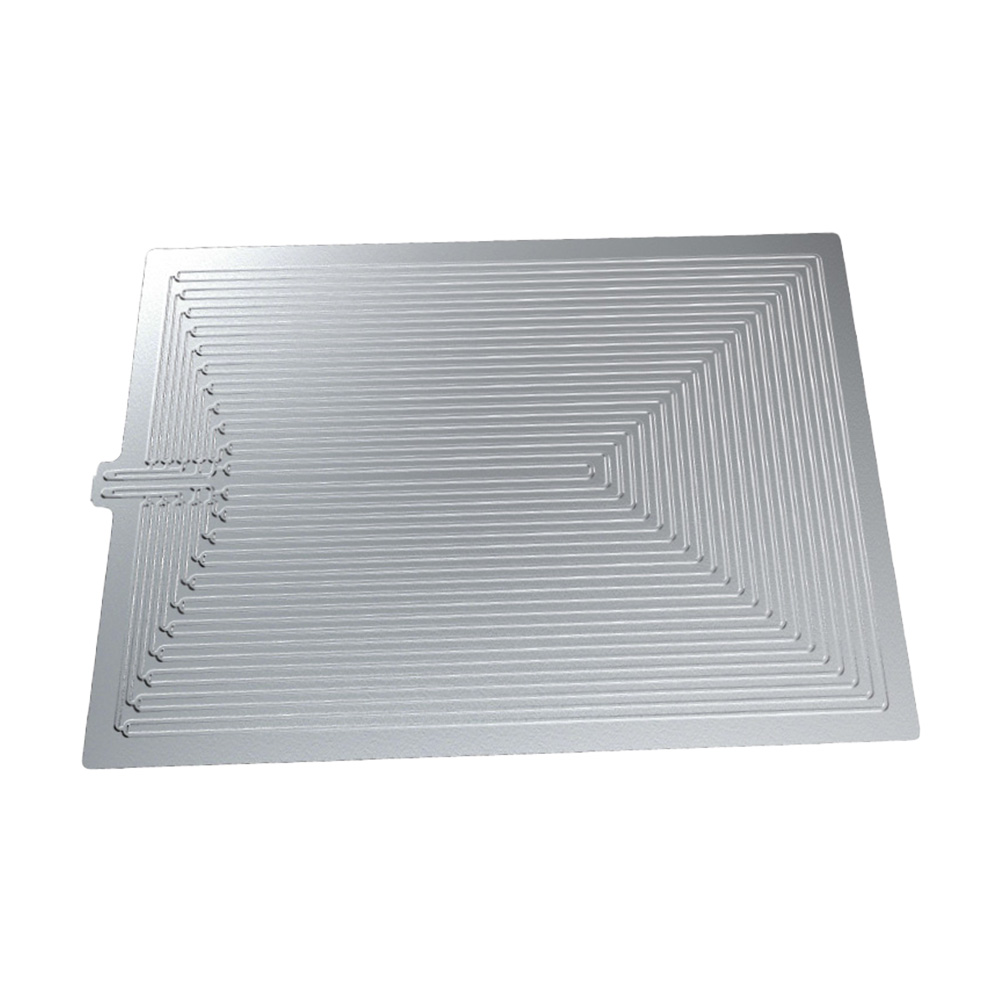

- Heat Exchangers: These vital devices transfer heat from the battery or fuel cell to the coolant without mixing the two fluids. The heat exchangers usually take the form of cold plates and are typically made of metal with a high heat transfer coefficient, such as aluminum.

- Coolant Pumps: These components circulate the coolant within the system. Electric pumps are typically utilized in EV and FCV TMS due to their precision control and independence from engine speed.

- Thermal Sensors and Controllers: These components continuously monitor the temperature throughout the vehicle and make necessary adjustments to the TMS, ensuring temperatures remain within safe and optimal ranges.

- Battery/Fuel Cell Heaters and Coolers: These elements help maintain the optimal operating temperature of the battery or fuel cell, a critical factor for performance and durability. Heating is achieved by utilizing a positive temperature coefficient (PTC) heater with heat-exchanging fin structures to distribute the heat evenly. A system of coolant, chiller, and heat exchangers achieves cooling.

TMS in EVs: Focusing on Battery Management

In electric vehicles, the battery TMS is a critical aspect of vehicle design. Batteries generate heat during operation, which, if not managed properly, can lead to reduced performance, safety issues, and shorter battery life. Lithium-ion batteries, the most common type in EVs, operate best at around 20-40°C.

Active cooling systems, predominantly liquid-based, are usually deployed to cool EV batteries. These systems circulate coolant via a heat exchanger, absorbing heat from the battery and dissipating it into the environment.

TMS in FCVs: The Heart of Fuel Cell Management

The fuel cell stack is the primary heat generator in hydrogen fuel cell vehicles. For optimal performance, the fuel cell stack must maintain an operating temperature of around 65-75°C.

Similar to those used in EVs, liquid cooling systems are also standard in FCVs. The heat exchangers are pivotal in managing the fuel cell’s temperature. Furthermore, waste heat from the fuel cells can be efficiently used to heat the cabin, enhancing the vehicle’s overall efficiency.

Challenges and Paths Forward

Designing TMS for EVs and FCVs presents the unique challenge of precise temperature control. Unlike internal combustion engines (ICE), where waste heat is ample, EVs and FCVs need active heating systems for colder environments. Furthermore, managing the heat generated during rapid charging (for EVs) or hydrogen refueling (for FCVs) is crucial.

As the technology for EVs and FCVs continues to mature, there are myriad opportunities for innovative TMS solutions. Advanced materials, better sensors, and more efficient cooling systems can further enhance performance, providing the next step in the evolution of these new energy vehicles.

Trust KUS for your Thermal Management Solutions

At KUS, we excel in engineering, design for manufacturing, and systems integration. We work with commercial and passenger vehicle OEMs, energy storage system providers, and repower solution providers to supply TMS components and system solutions. Our cross-industry application experience allows us to provide the best-in-class and off-the-shelf products that can be custom-designed for your thermal management requirements.

Contact us now to discover how our in-house design and manufacturing expertise can benefit you. At KUS, we always uphold strict regulations and are dedicated to the highest level of quality. From the initial selection of raw materials to the final assembly, we closely oversee every stage of the manufacturing process to ensure it meets and surpasses industry standards.